Who ever thought that “supply chain” would move into the popular lexicon in the way it has over the last 2 plus years? From the onset of Covid-19, to post pandemic inflation challenges, to global micro component shortages, everybody seems to know about supply chains. Everyone, it seems, can share a recent experience of when one let them down, but how many can get into the details of the what, where, when, who, how? Not many I would argue, even less when you dive into the world of Service Supply Chain (SSC), Aftermarket, Post Sales, Reverse Logistics etc.

The world of SSC has multiple unique characteristics that differentiate it from what most know as a supply chain.

SSC contains the majority of the procurement and delivery elements of supply chain. However, the levels of complexity in the final mile to the customer and their inherent nature being circular, make them far more challenging to manage. Sustainability presents challenges that traditional supply chains rarely have to consider as does the sheer volume of SKU’s/PID’s to be planned, positioned, recovered, repaired and reused. All of this against a backdrop of extending lifecycles, cost pressures, component availability and ever-increasing customer expectation.

Table source: modified from https://hbr.org/2006/05/winning-in-the-aftermarket (Cohen, Agrawal and Agrawal)

Certainly, in the world of B2C, with the substantial growth of internet purchase and returns, some of this complexity is creeping in, but the SSC has to deal with a myriad of demands, constraints and expectations that are rarely, if ever, present in a B2C or a B2B forward supply chain environment.

So, with all this complexity and the criticality of customer experience (CX) to every organisation, are there so few technologies designed to specifically support this environment?

You can certainly source most of the components – planning tools/systems, service order management packages, asset recovery/return tools – but there continues to be a preponderance of “home brew” and modified forward supply chain tools that limit practitioners’ ability to coordinate the plan – deliver – recover – reuse cycle and certainly don’t create the visibility this complex environment requires.

The potential of this environment is consistently underappreciated and its ability to impact customer experience regularly squandered. Gone are the days of build it, ship it, forget it, we have moved on in both B2B and B2C to an expectation of rapid response, prevention versus cure, uptime and availability, and lifetime/product lifecycle ownership.

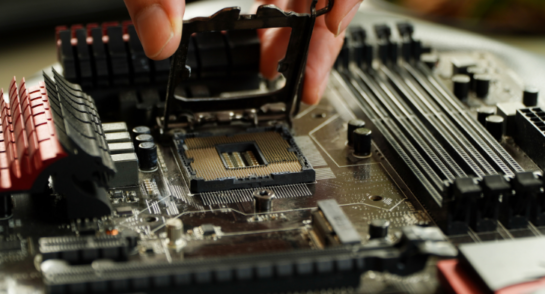

Software-enabled products not just at the core of an enterprise network, but now all the way to the edge, should allow data to flow from the device, to the technical/troubleshooting team, to the supply chain team. Built-in telemetry in many products can highlight possible failures or anomalies that allow both proactive diagnosis and intervention, be it a software patch or a hardware replacement. The issue is, it rarely happens that way. The majority of technical support and supply chain environments are disconnected or have minimal automated exchange. The case management systems may be common, but until an RMA event is triggered, there is no visibility within the SSC. Utilising the data from complex networks, understanding the behaviors of both software and hardware elements, analysing both failed and No Fault Found (NFF) components should enable improved positioning of inventory, planning algorithm accuracy, cost to serve, in life product quality, and ultimately the customer experience delivered by SSC.

The SSC’s ability to flex to meet these demands is a competitive advantage when it is orchestrated efficiently, when it’s not you will be reminded of every failure at every business review or sales engagement. Our role is to mitigate risk, not manage schedules and forecasts, and many companies/leadership teams don’t recognise this distinction. There can be mismatches in expectation when deterministic approaches are overlaid on an environment that is by nature unpredictable. The results of this mismatch can be poor levels of support through lack of material investment, and significant revenue left behind on the table.

To have a chance at winning in this environment, companies must invest in their commitment to both their products and customers. People, process and technology investments are critical to create a circular supply chain that can extend for years into the future, cement your reputation with your customer base and differentiate from your competitors.

What’s the answer?

People:

Understanding all the above issues, challenges and opportunities is a great first step, then building expertise in not just one, but all the elements of an SSC environment.

Building knowledge of how:

- Planning and procurement link to delivery and customer confidence

- Import/export compliance, product classification and valuation, geographic/market disruptions, local relationships and regulations all impact performance and experience

- Visibility and partnership with 3PL’s enable proactivity and consistency but also an ability to manage emergencies

- Asset tracking and install base management policy drive cost to serve

- Integration of communication and process with field engineers prevent unnecessary “truck rolls” or stranded parts at customer locations

- Recovery, reverse logistics and disposition of material support environmental and cost metrics

- Repair quality and yield rates become a critical resource for planning algorithms

- The velocity of this cycle impacts customer experience.

Process:

Consistency is key in any supply chain environment, but for an SSC it is critical. The interdependency of process throughout this ecosystem demands a different perspective and understanding of your value stream. Underpinning your operation with clear process and workflow allows for greater levels of automation, AI and ML to be utilised. Knowing that the majority of demands fitting within a tight set of business rules will be automatically actioned, allows the practitioner to focus on the critical, urgent or exceptional demands that could make or break a customer relationship.

Technology:

SSC is an environment hungry for innovation, and in my experience, full of innovators. They have to be, given the ever-changing landscape of customer experience, products, geographies, processes and the lack of SSC specific technology platforms.

As stated previously, SSC is not the same as a manufacturing supply chain, the demands are different, the needs are different, outcomes are different, so why is this not reflected in both the technology available and the investment by many companies? Why would there not be a platform approach designed specifically to serve this complex environment, not one treated as a “bolt on” to a manufacturing, ERP/CRM system?

We have a solution: our platform OnProcess Agora™

We’ve built a platform that has a data factory at its core, built in AI capabilities and the ability to both orchestrate and operate the SSC. It provides valuable and actionable insights from execution level to executive level. OnProcess Agora™ removes the need to modify, “home brew/DIY” or loosely couple together applications around an ERP solution.

RELATED CONTENT

Infographic: Is anyone using AI and Machine Learning in the Service Supply Chain?

Sign up for updates

Get the latest updates on our new services and fresh content — straight to your inbox.